| View previous topic :: View next topic

:: View posts since last visit |

| Author |

Message |

woodpekr

Joined: 25 Nov 2003

Posts: 235

Location: USA Oregon Portland

|

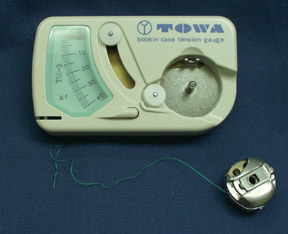

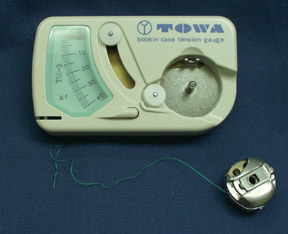

Posted: Wed Aug 18, 2004 2:11 pm Post subject: Bobbin Case Tension Gauge Posted: Wed Aug 18, 2004 2:11 pm Post subject: Bobbin Case Tension Gauge |

|

|

Check this out

details at:

http://columbiariverquilting.com/towa_bobbin_case_tension_guage.html

_________________

Rich Durant

Portland, Oregon

|

|

| Back to top |

|

KiteSquid

Master Kite Builder

Joined: 29 Aug 2003

Posts: 2796

Location: USA Virginia King George

|

Posted: Wed Aug 18, 2004 2:39 pm Post subject: Posted: Wed Aug 18, 2004 2:39 pm Post subject: |

|

|

That is one cool tool.

IIRC it is mostly used by industrial sewing machine mechanics to set bobbin tension.

$68 is a little much for me, even for a cool tool.

_________________

VR/

KiteSquid

AKA TakoIka

AKA Harold

King George VA

P.S. Yet another post by the Squid.....  Doesent he ever shut up??? Doesent he ever shut up???

P.P.S. The wind is like the air, only pushier. |

|

| Back to top |

|

Stan

Joined: 18 Nov 2003

Posts: 592

Location: San Diego

|

Posted: Wed Aug 18, 2004 2:44 pm Post subject: Posted: Wed Aug 18, 2004 2:44 pm Post subject: |

|

|

Does someone make a tool to calibrate the gauge?  |

|

| Back to top |

|

KiteSquid

Master Kite Builder

Joined: 29 Aug 2003

Posts: 2796

Location: USA Virginia King George

|

Posted: Wed Aug 18, 2004 2:49 pm Post subject: Posted: Wed Aug 18, 2004 2:49 pm Post subject: |

|

|

Stan is a true technician....

Every piece of test equipment MUST be calibrated!

_________________

VR/

KiteSquid

AKA TakoIka

AKA Harold

King George VA

P.S. Yet another post by the Squid.....  Doesent he ever shut up??? Doesent he ever shut up???

P.P.S. The wind is like the air, only pushier. |

|

| Back to top |

|

stevef

Administrator

Joined: 27 Aug 2003

Posts: 1279

Location: USA PA ALLENTOWN

|

Posted: Wed Aug 18, 2004 2:57 pm Post subject: Posted: Wed Aug 18, 2004 2:57 pm Post subject: |

|

|

cool tool, but I use the ole' flick-of-the-wrist technique:

1. Remove bobbin case

2. Hold thread between two fingers with bobbin dangling below.

3. Flick your wrist.

Observe results. If the bobbin falls to the floor, your tension is too loose. If the bobbin does not move at all, your tension is too tight. If the bobin drops and inch or two, the tension is just right and needs no further adjustment.

Fine tune the stiches thread tension with the upper tension adjustment.

_________________

Steve Ferrel

Go Build a Kite!

Measure once, buy twice!

Last edited by stevef on Wed Aug 18, 2004 3:33 pm; edited 1 time in total |

|

| Back to top |

|

woodpekr

Joined: 25 Nov 2003

Posts: 235

Location: USA Oregon Portland

|

Posted: Wed Aug 18, 2004 3:04 pm Post subject: Posted: Wed Aug 18, 2004 3:04 pm Post subject: |

|

|

I have to agree with all of the comments above . . .

I was just impressed/amazed that there was such a specialized gadget when all you have to do is the procedure that SteveF describes to get the tension right.

I wonder if the Bureau of Standards has a benchmark bobbin to calibrate the Bobbin Gauge against . . . .

_________________

Rich Durant

Portland, Oregon

|

|

| Back to top |

|

KiteSquid

Master Kite Builder

Joined: 29 Aug 2003

Posts: 2796

Location: USA Virginia King George

|

Posted: Thu Aug 19, 2004 7:14 am Post subject: Posted: Thu Aug 19, 2004 7:14 am Post subject: |

|

|

| woodpekr wrote: | I wonder if the Bureau of Standards has a benchmark bobbin to calibrate the Bobbin Gauge against . . . .  |

I could ask Bill Bigge.... as he retired from the Bureau of Standards and is a kite builder.

_________________

VR/

KiteSquid

AKA TakoIka

AKA Harold

King George VA

P.S. Yet another post by the Squid.....  Doesent he ever shut up??? Doesent he ever shut up???

P.P.S. The wind is like the air, only pushier. |

|

| Back to top |

|

Stan

Joined: 18 Nov 2003

Posts: 592

Location: San Diego

|

Posted: Thu Aug 19, 2004 10:56 am Post subject: Posted: Thu Aug 19, 2004 10:56 am Post subject: |

|

|

In a defense plant, I saw a mini torque wrench that was intended to turn one size of nut to one torque setting. It was the size of a fork and cost about $1,000. It was made by buying a $15 torque wrench and grinding a small notch in it. The markup was billed as "machining and testing."  |

|

| Back to top |

|

|